Fundamental Concepts of Stress and Strain

Introduction

Simple stress and strain is a very important topic for engineering students, especially for civil and mechanical engineering. It is the most basic chapter. In this article, we will learn about simple stress and strain, their classifications, and their applications. We will also see some examples of different types in another article to clear our misconceptions about stress and strain.

Stress

When a body experiences some external forces, it undergoes some deformation. Deformation means the change of shape (size, length, cross-sectional area, etc.). As the body undergoes deformation, the molecules of the body build a resistance force to deformation. This resistance force per unit area to deformation is called Stress. It is denoted by σ (sigma)

The unit of stress (σ ) is the “Pascal (Pa)” in the S.I. system.

1 Pa= 1N/m^2

The formula of stress-

σ= P/A

σ= Stress

P= Load acts on a body

A= Cross-sectional area of the body.

Elasticity

As we have discussed before, the force that acts on the body can cause deformation. This deformation can be of various types. The temporary deformation is called elastic deformation and the permanent deformation is called plastic deformation.

In temporary deformation, the body can come back to its original shape after removing the external force. The deformation caused by the external force within a certain limit is called temporary deformation. Such a limit is known as the elastic limit. And the property for which the material returns to its original shape is called elasticity.

The ability of certain materials to return to their original shape and size, after removing the external force, is called elasticity.

If the body returns completely to its original shape, it is called perfectly elastic. And if not, it is called partially elastic.

A strain is nothing but the deformation per unit length. It is denoted by ε

The formula of strain-

ε= δl/l or δl= εl

δl=The change of length of the body

l = Original length of the body

strain is a type of percentage. And so it has no units. It can be measured in meters per meter (m/m) or inches per inch (in/in) or millimeters per millimeters (mm/mm).

Main types of stress

The stress is mainly of 2 types.

1. Tensile stress

2. Compressive stress.

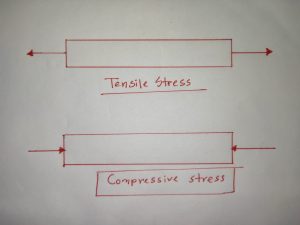

Tensile Stress

If a section of a body experiences two equal and opposite pulls, the body tends to increase its length. And so the cross-sectional area gets decreased. This stress is called tensile stress.

Compressive Stress

If a section of a body experiences two equal and opposite pushes, the body tends to decrease its length. And so the cross-sectional area gets increased. This stress is called compressive stress.

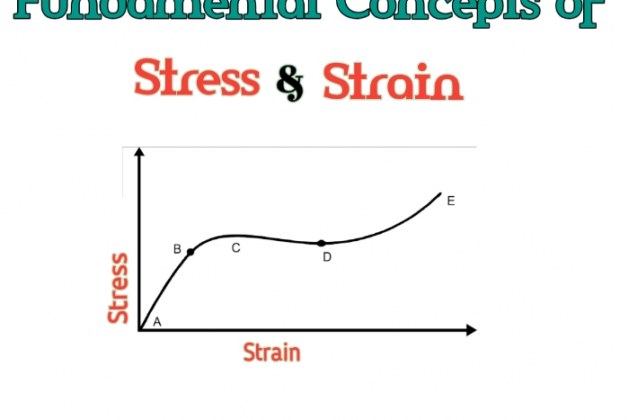

Hooke’s Law is named after Robert Hooke. He invented the law in 1678. The law states, “Within the elastic limit, the stress is directly proportional to the strain.”

That’s mean,

Stress∝ Strain

Stress/Strain= E= σ/ε

The constant “E” is known as the modulus of elasticity or Young’s Modulus.

The values of the modulus of elasticity of the important materials are given below.

| Si. no | Materials | Modulus of elasticity (E) in Gpa |

| 1 | Steel | 200 to 220 |

| 2 | Wrought iron | 190 to 200 |

| 3 | Cast iron | 100 to 160 |

| 4 | Brass | 80 to 90 |

| 6 | Aluminum | 60 to 80 |

| 7 | Timber | 10 |

| 8 | Copper | 90 to 110 |

Deformation of a body due to the acting force

P= applied force

l= length of the body

A= cross-sectional area

σ = Induced stress

E= modulus of elasticity

ε= Strain

δl= Deformation of the body

We know that,

Stress, σ= Force/Area= P/A

and

Strain, ε= stress/modulus of elasticity= σ/E

and so deformation, δl = ε.l = σl/E = Pl/AE= (Force*Length)/ (Area* Modulus of elasticity)

Notes:

- The formula can be used for both compressive and tensile stress

- In calculations, we use a positive sign for the tensile stress and strain and a negative sign for the compressive stress and strain.

Deformation of a body for its self-weight

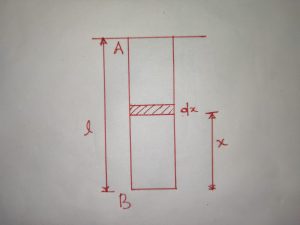

Let us consider a bar AB hanging freely under its own weight

Here,

l= length of the bar

A= Cross-sectional area of the bar

E= Young’s modulus

w= specific weight of bar material

Let us consider a small section of bar dx at a distance x from B.

The weight of bar for a length of x,

P= wAx

Elongation of the small section of the bar due to weight of bar for a small section of length x,

=Pl/AE= (wAx).dx/ AE= wx.dx/E

We can find the total elongation of the bar by integrating the above equation within 0 and l.

Total elongation, δl= ∫₀ˡ wx.dx/E

=w/E ∫₀ˡ x dx

δl= wl²/ 2E= Wl/ 2AE , where W= wAl= total weight

Principle of superposition

When a number of forces act on the sections of a body along the length, the resulting deformation of the body is equal to the algebraic sum of the deformations of individual sections. This principle is called the principle of superposition.

δl= Pl/AE= 1/AE (P₁l₁ P₂l₂ P₃l₃………..)

P₁= Force acting on section 1

l₁= Length of section 1

P₂l₂= Corresponding values of section 2 and so on

Shearing Stress

Another important type of stress is shearing stress or tangential stress. It is defined by τ (Greek: Tao)

Shearing stress can be of two types.

They are-

1. Direct shearing

2. Indirect shearing.

Direct shearing- When the stress is applied directly and parallel to the surface. There are three types of direct shearing. They are- 1.Single shear 2. Double shear 3. Punching shear

The formula to calculate average shear stress is the same as the formula of stress that is force per unit area.

τ= F/A

τ= the shear stress;

F = applied force

A = the cross-sectional area of that material

The formula may vary for single, double and punching shear. They are given below-

For single shear,

τ= F/A

For double shear,

τ= F/2A

Punching shear

τ= πdt

d= diameter

t= thickness

Our Facebook Page : ইঞ্জিনিয়ার'স থোট - Engineer's Thought A new post of the author- How to maintain good kidney health in proven 8 ways